Waterproofing process of Basement area: Ensuring long- lasting protection

Waterproofing of the basement is vital to protect the structural integrity of a building and also minimise water related issues. Following a well- planned waterproofing process helps to ensure that the basement remains dry, functional and durable. Whether you are a homeowner or contractor, waterproofing of the basement is mainly done for lower maintenance costs in long-term and also preventing any structural damages. In this blog, we will discuss the steps involved in Waterproofing of basement areas ensuring long-lasting protection to the structures by using products of FCSC.

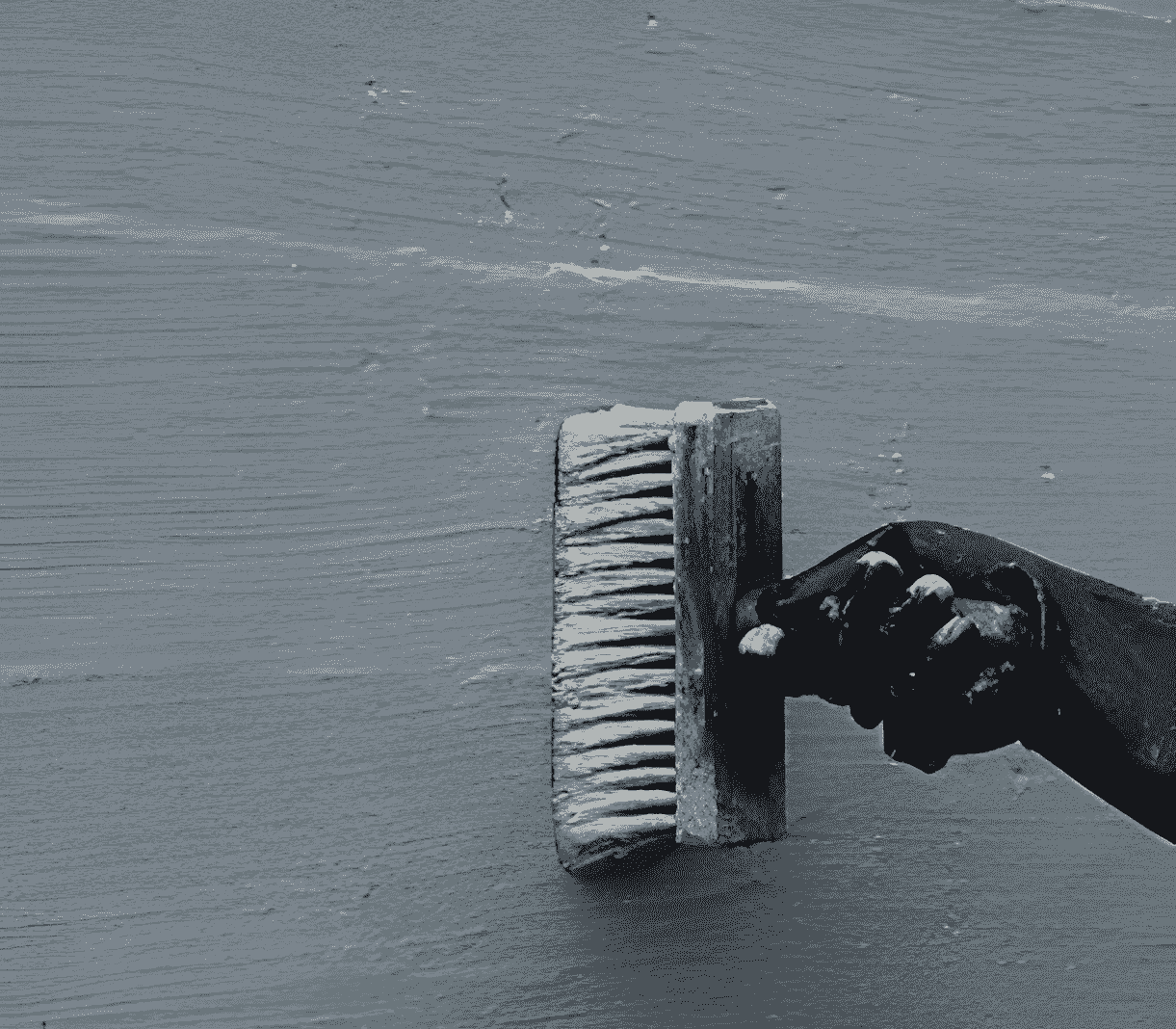

Steps of waterproofing process of basement area's

Step 1: Concrete repair and external rendering

Before Waterproofing of any structure, it is necessary to address existing damage like spalled concrete, cracks, debris and others. Key objective to repair the concrete is to create a stable base for waterproofing so that concrete structure can be long-lasting. At FCSC, we have CEMBOND SBR which is available in both B2C, B2B channels which offers high-performance to the concrete. It can be obtained as increasing concrete adhesion of repair motors to concrete surfaces and also making it ideal for precast slabs and others. Application of CEMBOND SBR can be done for external rendering so that the structure can get an additional protection from external influences. This product is best considering the construction context because of offering durable waterproof coating in basements, lift pits and inspection pits alongside water tower's and other structural parts.

Step 2: Grouting and Joint filling

After cleaning and repairing the damage in concrete, grouting should be performed especially in concrete joints. Key objective of performing grouting is to address cavities in concrete, filling of gaps and voids within basement concrete structures. CEMGROUT GP of FCSC is one of the best selling admixtures that are designed for Cementitious grouts used in bed grouting, duct grouting and non- shrink infilling. Our experts perform grouting for basement waterproofing particularly in column joints in Precast construction and anchors in concrete. Our CEMGROUT GP comes with higher flowability that significantly addresses all gaps and voids that helps to create a seamless and watering concrete joint that prevents water ingress. However, the presence of CEMGROUT GP has the capability of increasing performance of grout that keeps the basement durable and resistant to water infiltration. Overall, grouting by using this product ensures long-term protection against water or other external damages.

Step 3: Advanced Waterproofing

After repairing the concrete structures and grouted strongly, it opted for an application of advanced waterproofing solution in the basement structure. At FCSC, we have AQUAPROOF Crystalline available in both B2B and B2C that offers crystalline waterproofing technology for successful penetration of concrete and seals the gaps appropriately. AQUAPROOF Crystalline especially used for basement building, development of basement foundation and retaining walls. Application of AQUAPROOF Crystalline enables a permanent barrier against water that makes it a versatile solution for homeowners as well as businesses. However, advanced waterproofing through crystalline waterproofing is highly effective for protection of water ingress. For example- Basements in heavy rain often surpass its limit which can make it damp and also affects it long-run so, application of AQUAPROOF Crystalline able to protect the basements from water ingress and the structures remains ideal for a long time.

Step 4: Damp proofing and PU Waterproofing

In the context of waterproofing of the basement, damp proofing of walls is another key aspect for better protection. At FCSC, we have AQUAPROOF IW, available in the B2C channel which is a highly effective water- based epoxy concrete sealer. In making the basement walls damp proofed, this product offers an additional layer for better protection against water penetration. Apart from that, using AQUAPROOF IW is also ideal for roof slabs, screeds, basements, reservoirs and external plastering. However, AQUAPROOF IW can be used directly into the concrete that helps in increasing impermeability and also ensures the damp free basement. PU waterproofing alongside AQUAPROOF IW combinedly seal the gaps and also prevent the water from seeping through. Adhering to this technology, individuals can ensure water tightness in the basement structure and durability.

Step 5: Application of sealer

After waterproofing the concrete of the basement, it is necessary to seal the surface properly. In addition to AQUAPROOF IW, a water based epoxy concrete offers an additional layer of protection against water ingress. Application of sealer in the concrete provides durability, Waterproofing coating that significantly prevents water from penetrating the concrete and also ensures long-term resistance for the basement area's. Overall, with basement waterproofing with these products you can obtain significant results and also make sure the basement walls are damp free and also make it durable as well.