How accelerating admixtures play a vital role in enhancing the durability of concrete?

Concrete durability is important for structural longevity, particularly in environments exposed to harsh weather, high moisture, or heavy loads. Accelerating admixtures play a pivotal role in enhancing concrete durability, enabling faster setting and improved resistance to damage while helping to meet project timelines more efficiently. At FirstChoice Specialty Chemicals (FCSC) we have products like SPRAYCON A, SPRAYCON AF, SPRAYCON AFP, and SPRAYCON AF (LV) are prime examples of accelerating admixtures designed to enhance concrete’s performance. This blog explores how these products contribute to more durable, resilient concrete in construction.

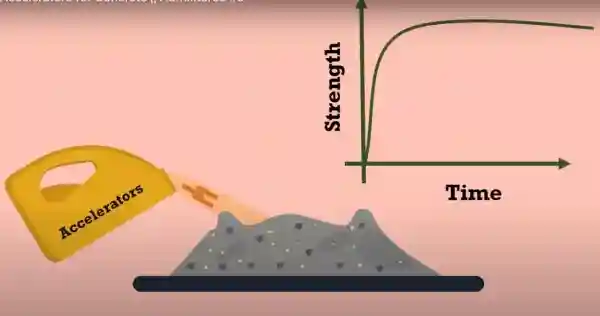

Faster strength development

Accelerating admixtures boost the initial strength of concrete, essential for projects with tight deadlines or demanding conditions. By speeding up the hydration process, accelerating admixtures enhance the early strength gain, making concrete suitable for structural applications more rapidly. This accelerated strength development reduces the waiting period for formwork removal or the application of additional load, streamlining construction workflows and supporting rapid construction cycles. Faster strength development is particularly advantageous in projects where timelines are stringent, allowing structures to be completed faster without compromising quality.

Improved Resistance to Early Water Infiltration

Concrete is highly susceptible to water infiltration during its early stages of setting. When water seeps into concrete too early, it weakens the structure, leading to durability issues and increased maintenance costs over time. SPRAYCON AF and SPRAYCON AFP improve concrete’s early resistance to water infiltration, providing a shield against moisture during critical initial phases. By enhancing the impermeability of concrete, these admixtures reduce the risk of internal cracking, efflorescence, and corrosion of embedded steel reinforcements, thus increasing the durability and lifespan of the structure.

Improved Resistance to Chemical Attacks:

Concrete with reduced permeability is better able to resist chemical attack from substances like sulfates, acids, and chloride ions. This is especially important in marine environments or areas where de-icing salts are used.

Enhanced Performance in Cold Weather

Accelerating admixtures are commonly used in cold-weather concreting to ensure that concrete sets and gains strength even in low temperatures. This is crucial for preventing freeze-thaw damage, which can occur when water trapped in the concrete freezes, expands, and causes cracking. By accelerating hydration, these admixtures help overcome the slowing effect of cold temperatures, ensuring that the concrete remains dense and robust against freezing conditions.

Reduced Risk of Cracking

Cracking is a common issue in concrete that compromises its durability and lifespan. Accelerating admixtures help minimize the duration and extent of drying shrinkage by enabling faster curing, thereby reducing the potential for crack formation. Since cracks can serve as pathways for water and harmful chemicals to penetrate, minimizing cracking improves the concrete's durability. Faster setting and curing reduce the potential for significant temperature gradients between the interior and surface of the concrete. This helps prevent thermal cracking, which can weaken the concrete and lead to future durability problems.

Shorter Curing Time

The curing process is crucial for concrete to achieve its intended strength and durability. However, traditional curing can be time-consuming, often extending project timelines. Accelerating admixtures cut down the curing time without compromising the structural quality. This shortened curing time allows projects to be completed faster, optimising resource use and reducing labour costs. With accelerated curing, construction schedules become more manageable, particularly in time-sensitive projects. Shorter curing times also allow for earlier application of protective coatings such as water-based epoxy concrete sealers, further enhancing durability and resistance to moisture and abrasion. ruction.

Benefits for enhanced- concrete durability

- Precast Concrete: In precast concrete applications, where speed of production is critical, accelerating admixtures enable faster curing, allowing products to be removed from forms more quickly without compromising long-term durability. This is essential in high-turnover projects, such as in the construction of tunnels, bridges, or infrastructure elements that must withstand harsh conditions.

- Repair Works: For concrete repair, accelerating admixtures can be used to enhance the bonding and early strength development of repair mortars, reducing the risk of re-cracking and increasing the longevity of the repair.

- Resistance to Alkali: Silica Reaction: Accelerators can reduce the risk of ASR (a reaction between alkaline cement and reactive silica in aggregates) by promoting rapid hydration and reducing the time frame for the reaction to occur. A more rapidly hydrated concrete can limit the formation of expansive gel, which is responsible for cracking in ASR-affected concrete.

- Concrete Exposed to High Temperatures: Accelerating admixtures can be beneficial in structures exposed to elevated temperatures (like pavements or industrial floors), as they can increase the rate of hydration and help achieve a denser, more stable microstructure, reducing the risks of thermal cracking and degradation.

Overall, Accelerating admixtures like SPRAYCON series products are essential in numerous applications, from residential buildings to heavy industrial projects. At FCSC, we offered these solutions available in B2B for faster setting, enhanced strength, and increased resistance to environmental stressors. Additionally, when combined with waterproofing primers for concrete, metallic and non-metallic floor hardeners, and water-based epoxy concrete sealers, these admixtures contribute significantly to the longevity and durability of concrete in challenging environments.